First years of Chemische Fabrik Vorster & Grüneberg, Cöln

The merchant Julius Vorster and Hermann Julius Grüneberg, a chemist and pharmacist, founded the Chemische Fabrik Vorster & Grüneberg, Cöln, on November 1, 1858. Grüneberg had succeeded in producing potassium nitrate by reacting sodium nitrate and potassium carbonate. He had furthermore discovered a process for the industrial production of potassium chloride from potash salts.

The production of potash salts began in 1860 in the village of Kalk near Cologne. Dr. Grüneberg had potash salts transported by rail to Kalk from an old salt mine near Staßfurt. They were dissolved here in wooden vats with steam and, after cooling, crystallized out of the solution again. The resulting intermediate products were again dissolved and crystallized out until pure potassium chloride was obtained.

This was the first factory processing of raw potash salts and hence the beginning of the German potash and fertilizer industry.

Grüneberg and Vorster recognized at an early stage that, in addition to potassium and phosphorus, the agricultural sector also needed to be offered components containing nitrogen. Ammonium sulfate and superphosphate were therefore added to the product range for the first time in 1865, and with them the first industrially produced compound fertilizer.

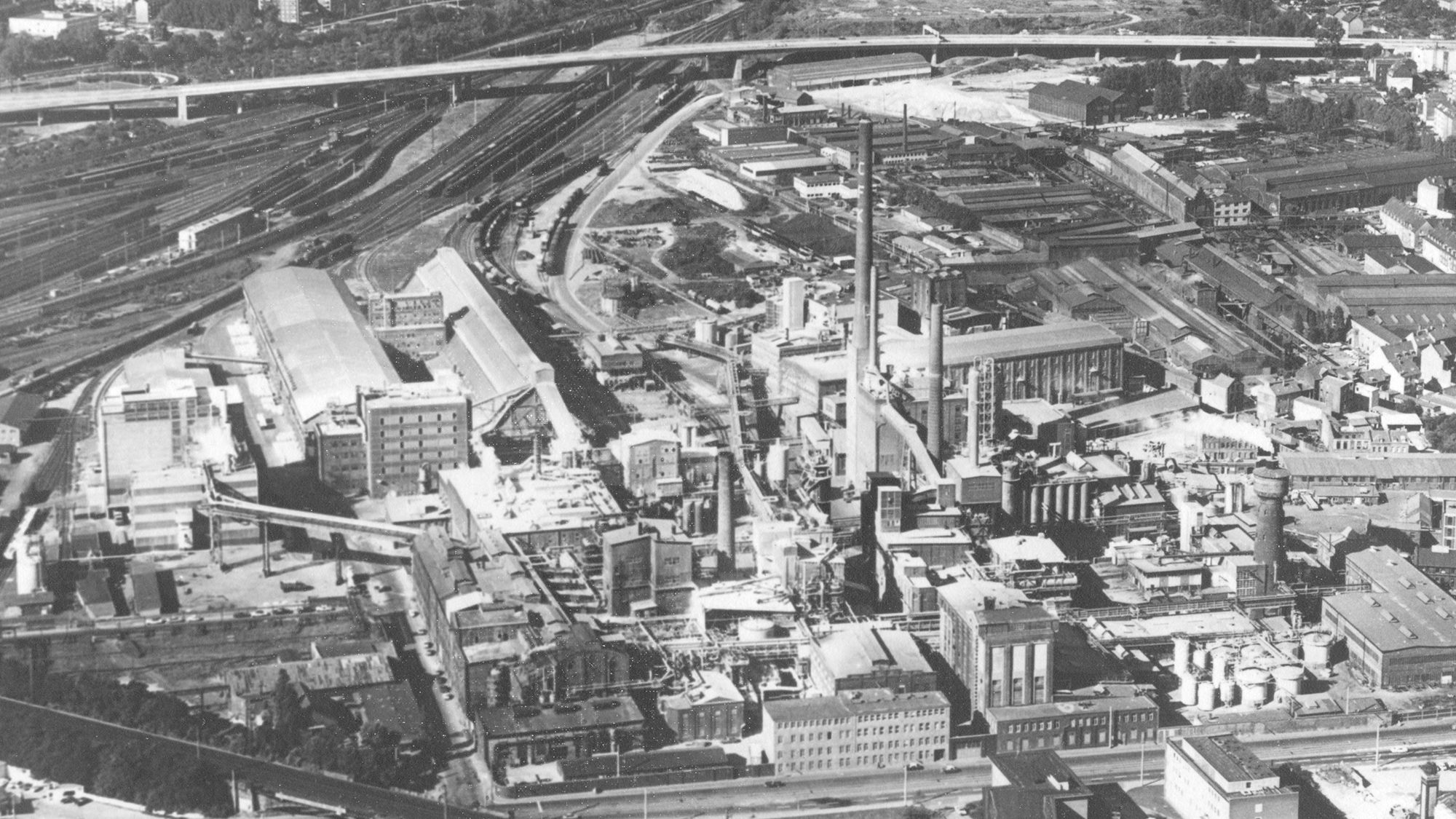

Renaming as Chemische Fabrik Kalk GmbH

Vorster and Grüneberg made practical use of the Reich Law on a new form of limited liability company promulgated in April 1892 just three months later by changing their company name to Chemische Fabrik Kalk GmbH (CFK). This made it one of the first and oldest German limited liability companies with an unchanged name ever.

Despite great successes in the fertilizer division, heavy chemicals such as potassium nitrate, potash, sodium sulfate, ammonia solution, and ammonia salts became the company's real profit earners.

Shortly after the turn of the century around 1900, soda production commenced using the ammonia process. Even then, huge quantities of soda ash were needed for the manufacture of glass, detergents, pulp, artificial silk, etc.

In the spring of 1920, Alfred Vorster entered into an agreement with the chief chemist of the Stinnes Group, Dr. Alfred Pott, under which CFK was dedicated to the further processing of purchased ammonia into finished fertilizers and their marketing to the agricultural sector.

The Second World War

The Second World War, which began shortly afterwards in 1939, put an end to all plans for the time being. After the National Socialists came to power, the company's activities were dominated by measures to prepare for war.

As early as 1942, during the first Allied bombing raids on Köln-Kalk, the production facilities suffered severe damage. The plant site in Köln-Kalk was 80 percent destroyed.

Restoration and increase of production volumes

Following repair measures, the first tonnes of ammonium sulfate could be delivered again from 1946, and soda production also resumed in 1949; in 1950, CFK had finally reached its former production volume again.

In the last 1950s and the first 1960s, CFK developed and produced feed phosphates that were used in animal feed mixtures for phosphorus supplementation. At that time, CFK was one of the largest producers of feed phosphates in the FRG.

Other new products in the early 1960s were liquid flower and garden fertilizers, which were marketed first under the name Dr. Glücks Blumenpflege and later through COMPO GmbH.

Merger and market expansion

In 1971, Salzdetfurth AG, CFK's parent company from 1960, merged with BASF subsidiary Wintershall AG. A year later, the company was transformed into Kali und Salz AG.

Shortly after the takeover by BASF, CFK began to additionally produce flower and garden fertilizers, which were distributed through COMPO GmbH.

Advancing automation of operational processes and modernization of plants caused a reduction in the workforce in the 1970s.

In the following years, the processing of calcium chloride into mining products opened up the market for dust binding agents in the mining industry. In new plants, high-purity calcium carbonate such as pure calcium chloride was produced in accordance with the European Pharmacopoeia.

In 1988, fertilizer production was terminated. The production of calcium chloride and soda ash was discontinued at the end of 1993 for economic reasons. Starting 1994, all parts of the plant were shut down.

All buildings and equipment on the site were dismantled in the following years and the property was sold after its redevelopment.

Trading company for basic chemicals

Since the discontinuation of production in 1994, CFK has been working successfully as a trading house for basic chemicals (acids, alkalis, and solids) with various European producers and distributes its products mainly in Germany and neighboring European countries.